ECM motors are commonly used in HVAC systems these days as blower motors.

This includes air conditioners, heat pumps, and furnaces. ECM Motors can adjust the airflow depending on what the system is getting for feedback.

First of all, there are two components to an ECM motor the control module and the motor itself.

The motors by far fail the most, but the control modules can also fail.

If the motor fails, it can simply be replaced. If the control module fails, it needs the chip to be programmed for the unit.

ECM modules have a common failure: a thermistor that goes bad, and it is common for these to fail.

Basics Steps to Locate the Problem with an ECM Motor

- Set the thermostat to Blower, which should send 24 volts to G (blower) and C (Common) terminals.

- Use a multi-meter and verify 24 volts DC is being supplied at the thermostat G (Blower) and C (Common) terminals.)

- Use a multi-meter and verify the motor is getting power. (There should be a high voltage of 115 volts or 220 volts.)

- Power the unit off at the breaker or pull the disconnect so the system has no power.

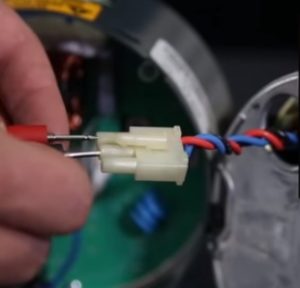

- Separate the control module from the motor.

- The three wires which go into the motor should be tested for resistance from one to the other.

- Test for resistance to see of the motor windings are good, and each resistance value should be close to the other within 10 percent.

- Also, check each leg of the motor wires to the case to see if one has shorted out.

- If the values are wrong, then the motor is bad.

- If the values are correct and the motor spins well, then the ECM is likely bad.

Summary

The above are the basic steps to help narrow down a problem on suspected bad ECM motor.

There are more tests that can be done, including with the right diagram for your motor jumping the harness to get the motor to run.

More than likely, it will be a bad motor, as in my experience this is the most common failure, and it will need to be replaced.

The ECM control modules fail also, so be sure to verify it has gone bad.

Remember, the control module is programmed to work with that unit, so it must go back on a new motor.

There is a common failure on ECM motors with the thermister going bad. Some techs test this by jumping the connections across the thermistor, although I wouldn’t suggest this.

Control modules should be bought from the manufacturer. Remember, a 2.3 module from Rheem cannot be used on a 2.3 motor for a Trane system even if they look the same.

There are many problems that an ECM motor can have. Sometimes it is simply a pin on a Molex connector that needs to be pushed in; other times, the entire unit can be bad.

Caution must be taken when dealing with any HVAC system as there is high voltage in any system. Do not attempt to repair a unit yourself unless you have had training in proper high voltage practices and safety.

I have a carrier ECM unit fail – original ECM was from 2014. I purchased a “direct replacement” ECM. when installing i noticed the wiring harness that connects to the rotation sensing unit just had a dummy connector on the ECM board – so it has a receptacle for the speed sensor but there were no pins on the board. I was advised by my A/C guy to just try it to see if it works. so far so good, it works with out that part of the circuit. does anyone know if this is normal? did they somehow upgrade the ECM to not use the rotation reference sensor? idk how but it is working.

I am trying to troubleshoot a GE ECM 2.3 Motor inside a Rheem furnace. The motor does not run. When the Fan is in the ON position on the thermostat, I have checked that the control board receives 24VAC from the thermostat on Terminal G (and I hear a relay click, most likely for fan). In attempts to test the motor while isolated from the control board, I have confirmed that the motor has 115 VAC on its 5-pin connector. In addition, I have applied 24VAC to pins 12,15 of the 16-pin connector while pins 1,3 were connected to the common C. Still the motor did not run. This is telling me that the motor is faulty (assuming the pinout for the 16-pin I found on the web is correct!). However when checking the voltage on the male 16-pin connector on the control board, pin 12 gets 24VAC but pin 15 gets only 0.5VAC. Shouldn’t pin 15 get 24VAC also, if the control board is healthy? (I understand/assume pin 15 is for the Fan and pin 12 is the supply to the motor control module). Does this mean both the motor and the control board are faulty? I wish not!

ICP wapm364a2 variable blower motor starting problems. It starts up then stops then starts again by itself. Of course not every time. Any Ideas what the problem is?

If replacing ecm module does the supplier need to program it to my unit?

I want to know this as well. Can get an unprogrammed (bare) module that the seller claims can be programmed for my unit – but who by? The oem dealer or any technician with the a programmer ?

I have a 2006 Bard Geothermal . It has a GE 2.3. I think i have a bad bearing. It has a shudder on start up. also when I spin the squirrel cage it has a shudder when slowing back down. also has a rattling sound when running. I’m in Michigan and not sure on what motor to order. too cold to pull apart and wait for a motor. I called bard and the distributor, they want to sell me the whole new GE 2.3 unit. very expensive! You mentioned the motors are basically the same. Sorry, but you were short on the motor Part. Trying to figure out what motor to order

I believe I have a Genteq 2.3 motor in my York Affinity modulating furnace. The furnace control board has an LED that flashes between 1 and 13 times to indicate blower CFM. All seems fine at the lower speed/heat operation but as it ramps up, with a longer call for heat, and gets to 8.5 or 9 LED flashes it will drop down to 5.5-6.5; after about 20 seconds of reduced airflow the temperature limit switch kicks in. The furnace then kills heat, ramps the inducer and blower up to cool things off, after about 2 minutes it’s back up and running again. For maintaining heat in -15C we seem to be okay but if I want to raise the temp or we hit colder weather the extended call for heat brings the problem back. Any initial thoughts before I start opening up the motor for testing?

I just picked up a new ecm motor for a lennox. I wanted to test it before putting it in so I used my tecmate inspect. To test it.

Connected the 16point harness and the 24 volt leads to the 24v side of the transformer. Turned on tecmate. Motor start but it ramps up and down about 5 times and then quits spinning. Voltages and ground are.all good. Also tried jumperimg the motor though the 3 and 15 pins on the harness and wiring the 120 direct to another power source bypassing the furnace all together. Same result. Could the new module and blower be faulty. Module portion, tjermosto or capacitor?

This will be very useful for every one try to make a Bench Test for any ECM Motor on the BENCH, I lost 2 weeks in deep investigation for having the same problem for many good and new ECM Motors and all of them got tested on the BENCH with 120V and just the 24DCV having the Motor Shaft free running not connected to any Load or fan or Blower or turbine and I got the same result for having the Motor spin fast then slow then fast then slow and so one, this is not a problem but the reason that these Electronic Motors needs the Blower to be installed on the Shaft because the Motor need to sense the Air Flow resistance and adjust its direction first then adjust its speed also according to the Air Resistance but you can not leave the Shaft alone and expect a constant speed (remember that these Motors maintain constant air flow with variable speed ageist different resistance so Air resistance has to be present in the test to show you stable speed)

whoa man you saved my ass there! I was about to send the motor back

Hi can you help? When running one of these motors on 240V how do you reverse the direction? Can you swap the RED and BLACK wires to the motor from the ECM or do you swap the RED and BLUE wires? or neither?…

This information given above is not credible, it is the module which is the “more common failure”, NOT the motor ! The motors don’t fail that often. I do HVAC repairs for a living, have done so for nearly 20 years. But yes, check the motor winding resistances as described, then the motor to case resistance (it should be infinite ohms) … if these appear okay, the module is likely at fault, but it could also be the integrated fan board that is at fault, or the control transformer, or the wiring harness between the fan control board and the ECM motor module.

My Carrier has a Genteq 2.3 ECM module. A week ago we had a problem with the heat pump compressor running but the blower not rotating. Opened up the air handler, tried spinning the blower but didn’t start up. Turned power off, then on, watched blower rock back and forth a few times, but still wouldn’t start up. Spun it again a couple of times, and eventually it started up. A couple of hours later had same problem. Got it to start again, this time with thermostat Fan setting to always On, and heat pump ran normally with no problem for several days.

Then turned it off, took motor out to check windings – all checked about the same 4.5 ohms or so, none shorted to ground. Turned it back on, still with Fan Mode always on, and has been running fine ever since.

Any idea why the intermittent failure of the fan motor to start turning normally after having been off? All electronics seem to be working fine as long as I keep the Fan Mode always On.

Hey Al..

What was the fix for your issue? My AC is doing something similar. Thanks

Hi James,

Don’t know if you’ll get this, but here is the situation. The “fix” was to put thermostat in Fan ON mode, rather than Fan AUTO. Once the fan starts it will keep running indefinitely. So, just today (11/3/21), I noticed it was cold and realized that the air handler fan was not running. Looked at the thermostat, and the Fan mode got changed to AUTO, probably due to a power line glitch we had yesterday. I eventually got the fan to run again by powering off the unit several times, waiting a while and powering it on.

I’m guessing it is the motor itself or something intermittent in the ECM control module attached to the motor. I bought a TecInspect tool which I had not yet used, and was about to test the motor with that tool, but buy that time it had started up again. I’m looking into buying a remanufactured Genteq Motor with attached ECM module, which will set me back $400. That’s cheap if it turns out the Genteq motor/ECM was the source of the problem, but expensive if it fails the same way after putting in the reman motor. Mulling it over right now.

Hi John. I have two blowers, both with the Genteq EON 1/3hp motors. They have a 5-pin 120/240VAC and16-pin controls connectors, so in assuming it’s the 2.3.

I have the 5-pin wired for 120V but I don’t have anything for the controls, as I only want to use these as constant speed outdoor air movers, and not be controlled by a t-stat.

Is this scenario possible with this motor?

How can I go about troubleshooting my issue. Weak airflow out of the vents I can’t even feel any air so I opened up the air handler and noticed the blower is working although it makes some noises like it is trying to go to higher speed but it can’t. If I reset the breaker it will blow fast and I get great airflow out of the vents for about 5 or so minutes and then it will slow right back down to slow speed where I can’t feel anything out of the vents.

How can I troubleshoot this to confirm the faulty component?

Thank you for posting this. Most of us do not understand the variable Pulse Modulated Motors work.

Very helpful! I used this to find a blown Thermistor on my GE ECM control module. The part is labeled SG348, but I cannot find that exact part number to purchase. Do you know what would be the correct replacement thermistor part number or spec? Thanks–I hope this fix works!

I realize this comment is late but, FYI, Digikey ICL (Inrush current limiter) SG379 (570-1463-ND), 1 OHM 25% 30A 31.75MM, should work just fine in the ECM module. My ECM module failed a couple of weeks ago, smoked ICL disc. Also replaced the bridge rectifiers as a precaution.

I have a Rheem home ac and the air handler fan motor will not shut off. The thermostate has been tested and it is fine The only way to shut off the fan is to shut off the breaker . I suspect it is the ECM module. Can this alone be replaced or does the entire unit need to be replaced? Where to buy? Thanks.

I have the same problem. Older Rheem Classic 4-ton RHLA-H4821JA. Will not turn off, even with thermostat and control board disconnected. Starts and stops randomly. Heat and A/C operate correctly. Are there any other potential trouble spots to look at before purchasing a new ECM module?

I have two air conditioning units, one unit has ecm motor and the other has psc motor.

the unit that has the psc works very good for 15 years

the unit that has the ecm motor, I have changed three times in 5 years, so where is the savings?

ecm motor is very expensive, so the last time the ecm motor was damaged, a psc adapted and is working very well.

the psc is little less efficient than ecm, but it is more durable

The motor ecm was easily damaged.

how can you slow down an ECM motor from spinning to fast. Its way too loud when operating and I can really hear the air coming through the vents. what can I do?

I have a Rheem RH1T3621MTANJA, the fan doesn’t get up to speed. It starts very slow and stops about 5 seconds later. I replaced the ECU board and had the motor reprogrammed, which it said it accepted it. Do you think the ECM is bad?

Did you ever get this issue fixed?

@Rick H

You have a sticky resistor. Can hit it to work but will need to be replaced eventually.

My ac quit working…had ac techcome out ( actually 2 different techs from 2 different companies) both told me blower motor and module went bad. So bought a new one but genteq instead of trane. Installed new set…still didnt work. So we bought and replaced the control panel as well. Still not working. So thinking we got a bad module/motor we exchanged them out ajd installed new ones…STILL NOT WORKING. All wiring, voltage and etc checked and triple checked… Beyond thinking…what else could possibly cause this. Two more (different) ac techs are flabergasted by this.

you answered your question,

You have to put the manufacturers OEM ECM motor back on it.

can’t use other mfg ecm motors.

You mean you can’t use a Genteq ecm in place of the GENTEQ MADE motor in the trane?

Ummmmmmmmmmmmmm

Just make sure you get the same motor (model on motor) and ECM that is programmed for the motor (model on ECM 2.0, 2.3, 2.5, 3.0, EON) or X13

I know this is old but bob is correct. Each HVAC manufacturer (Trane, Rheem, York) has their own program running inside the EMC module. How they translate the signals from their control boards into 3 phase motor signals is custom to their ECM module. Genteq only manufactures the motor and ecm modules. They don’t dictate what the programming will be.

I just purchased a motor module gentec for my rheem system motor. Its the exact replacement unfortunately when it arrived it says on it programmed for a Trane motor.

Can it be reprogrammed to be used with my rheem system?