Evaporative swamp coolers need basic maintenance every year for them to work well and last many years.

Oiling the bearings on the rib cage fan is one of those things that should be done yearly.

Keeping them oiled up is an easy task that helps them last longer and avoids having to replace the bearings.

Replacing the bearings on a swamp cooler is a straightforward task but can be a real pain. This is why keeping them maintained is always a good idea.

Below is a quick overview, steps with pictures, and a video if needed.

What Kind of Oil Do You Use in Swamp Cooler Bearings?

The most commonly used oil for swamp cooler bearings is Zoom Spout.

It is widely used and has a pull-out nozzle to fit into the tight space and opening.

If Zoom Spout is not available use a light machine oil and stay away from any heavy type of grease.

Example, Zoom Spout Cooler Oil on Amazon

Dial Manufacturing 5713 4-Ounce Zoom Spout Cooler Oil

How Often Should You Oil the Bearings in an Evaporative Swamp Cooler?

Bearings in a swamp cooler should be oiled every 2-3 years.

Many homeowners will oil them every year as a preventative measure to help the cooler last longer.

While cooler bearings can be replaced it is much more involved than oiling them.

Overview for Oiling an Evaporative Cooler Bearings

- Buy the correct oil, such as Zoom Spout

- Remove the side panels

- Locate the oil Fill Holes

- Drip oil into the Fill Holes

Steps to Oiling an Evaporative Cooler Bearings

- Turn Power off to the unit.

- Remove the side panels on the swamp cooler.

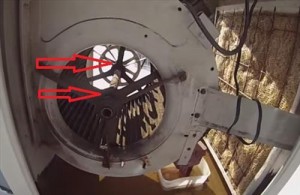

- There are two bearings in a swamp cooler on each side of the rib cage fan. The oil is dripped into small covered holes located on the top of each bearing housing. A small tab will cover the hole and simply needs to be lifted up on one side.

- Zoom Spout oil bottles come with an extender to drip the oil into the oil holes.

- Fill each oil hole to the top.

Do Swamp Coolers Need to Be Oiled?

Yes, swamp cooler fan cage bearings need to be oiled every few years.

The cage spins two bearings located on both sides of the unit.

The motor turns and spins the fan cage, which blows cool air into a home.

Both bearings should be oiled as part of preventive maintenance.

What Happens if Swamp Coolers Bearings are not Oiled?

If the bearings are not oiled, they will become noisy and eventually fail.

Once the bearings fail or seize, the fan cage will either not spin at all or make a very loud noise and racket.

If the bearings go bad, they will need to be replaced.

Summary

Oiling the bearings on a swamp cooler is not d ult and done by many hone DIY type of persons.

Often the most difficult part is the location of the swamp cooler.

For example, if the cooler is located on the roof, it will be more difficult than one located on a wall close to the ground.

The side panels will need to be removed to get access to the oil fill holes.

There are two oil fill holes that will be located on either side of the motor cage.

Simply fill each bearing hole up with oil, and the cooler should be good for another year.

This simple task can help prevent the pain of having to replace the bearings later on and add to the life of a swamp cooler.

Have you oiled the bearings on a swamp cooler? Let us know your thoughts below.

I oil mine with Amsoil 20 weight non-detergent synthetic air compressor oil. I get a quart, and small oiler bottle with application tip off of Amazon. It works amazing! Plus I use the oil for various other things as well.

I add oil at the beginning of the season, and about halfway through. During the winter I’ll bump it on low ventilation for a few seconds just to rotate the equipment to circulate oil, and prevent the motor bearings from getting a flat spot from sitting in the same place For long periods.

I have a 10 year old Brisa window mount cooler. last year it started spitting fine bits of oil into the room, getting on the carpet — not good. So what causes that? Otherwise the cooler has been maintained at the start of each season and some repairs have been done over the years and the motor was replaced. But that oil coming in the house is a real problem. What do you think?

Servicing mine for the first time (new house, obviously hasn’t been maintained in a bit) and the cap near the belt is missing and it looks like the hole where I put oil in is gunked up. What do I do?

That happens a lot just fill the hole with oil. The caps keep out dirt which can damage the bearings.

My question is do you have to oil a BRAND new swamp cooler or are we good to go u til next season?

It most likely has oil but couldn’t hurt to add some.

How much oil is necessary to lubricate the bearings of an evap cooler. I do not think there has been any maintenance performed on this cooler. Ever. I have replaced pads, pump, belt and have now lubed the bearings in the small reserviors on each side of the shaft. It was quiet overnite but I think I must go up on roof again to put more oil in or at least check

Fill up the hole were it is added. You could fill it, let it run a bit and fill it again if you think they are dry.

Thank you for this video, and the written instructions as well!. I heard a strange sound when the roof top swamp cooler was on last night. I had the Zoom container in the cabinet I knew, so I looked up your video, and decided to try and fix the problem by myself this morning. The pictures with the red arrows helped a lot! I’ll admit that I was a little nervous, climbing up on the roof this morning to see if I could remove the side panels off, as the cooler is on a slanted roof. But I did it~ and i just wanted you to know that I am a 63 year “young” woman, and i did it myself! Woo hoo~ Thanks again!

You go girl! WOO HOO! 🙂